Pulley Lagging Sheets

Pulley Lagging Sheets

Rubber lagging Sheeting are available in Plain, Grooved, Stud profile. Widths up to 2m in continuous length rolls or segmented strips are available. Rubber compounde

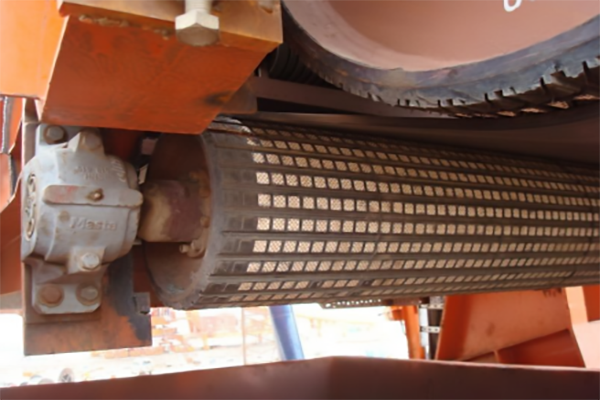

CERA LAG-Ceramic Embedded Rubber Lagging Sheets

CERALAG sheets are ceramic tile embedded lagging sheets used for extreme application subjected to, wet/slurry conditions, high speeds, high tonnage, long

About us

From its inception in 2012, Thejo Australia Pty Ltd., has grown today into a pioneer in belt splicing and pulley lagging, rubber lining, manufacture & supply of splice kits, manufacture & supply of splicing/ pulley lagging products, supply of conveyor products and supply of belt maintenance equipment.

ADDRESS

Head Office & Perth Workshop

22 Tayet Link, Bibra Lake, WA 6163

Kalgoorlie Workshop

37-39 Oroya Street South Boulder WA 6432

Pilbara Workshop

7 Oxide Way, Wedgefield, Port Hedland, WA 6721